Screen Printing

Screen printing uses a mesh to transfer ink on to the product surface. First, a stencil of the negative image is made on a mesh. A squeegee or blade is used to fill the open mesh apertures with ink, and a reverse stroke then transfers the ink on to the product. This is an automated process that can be done with great speed and precision. In large quantities, screen printing results in economies of scale.

Example

Screen printing is an important part of the industry because of the high quality and consistent products that it produces. We use screen printing in a number of our printing methods, including the following.

Water Transfer Decals

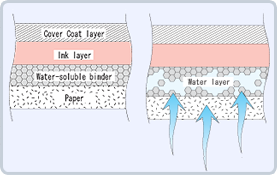

Water Transfer Decals, as known as water slide decals, consists of several layers including a cover coat, ink, water-soluble binder, and a paper backing. After being placed in water for a few seconds, the water-soluble binding will become slippery and allow the decal to slide off the paper backing. The decal is then transferred from the paper backing to the product. This works best if the surface of the product is gloss or semi-gloss. The surface can be flat or curved. Excess water is removed with a squeegee and the product is left to dry before being fired in a kiln.

Example

Thermal Transfer

Thermal Transfer is a printing method that permanently places the image using heat and pressure on to the product. This is an automated process that can be done with great speed and precision.

Example

Copper Plate Transfer

Copper Plate Transfer is used for products that want a copper finishing on all or part of the product. It applies well on unglazed ceramic surfaces.

Example